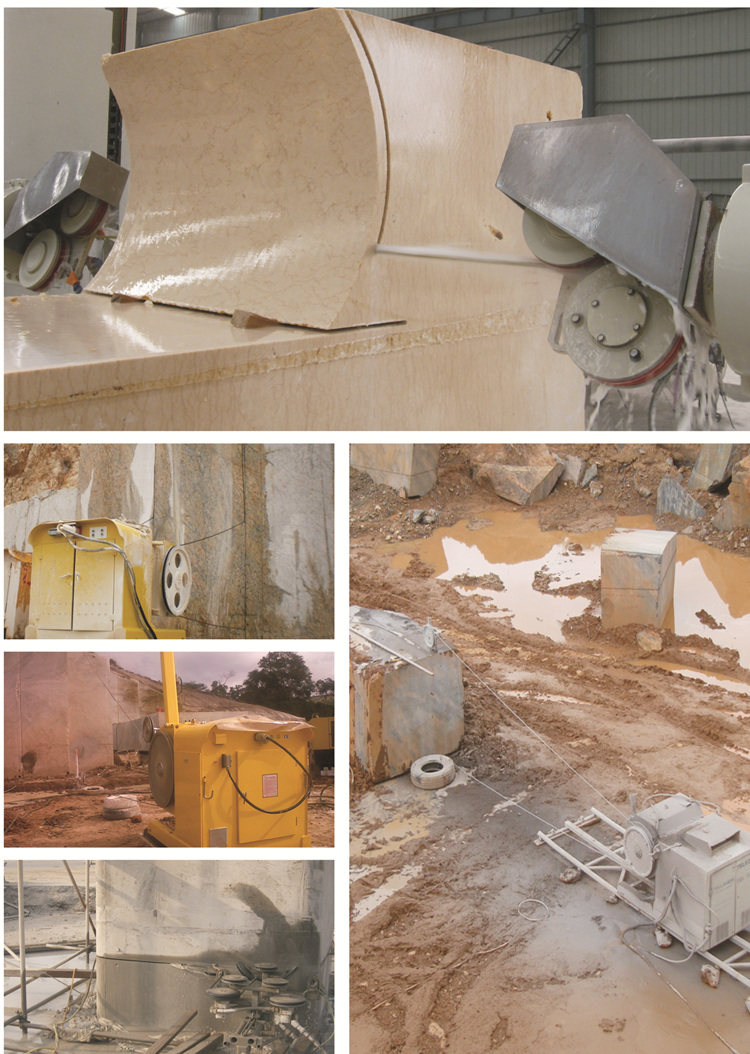

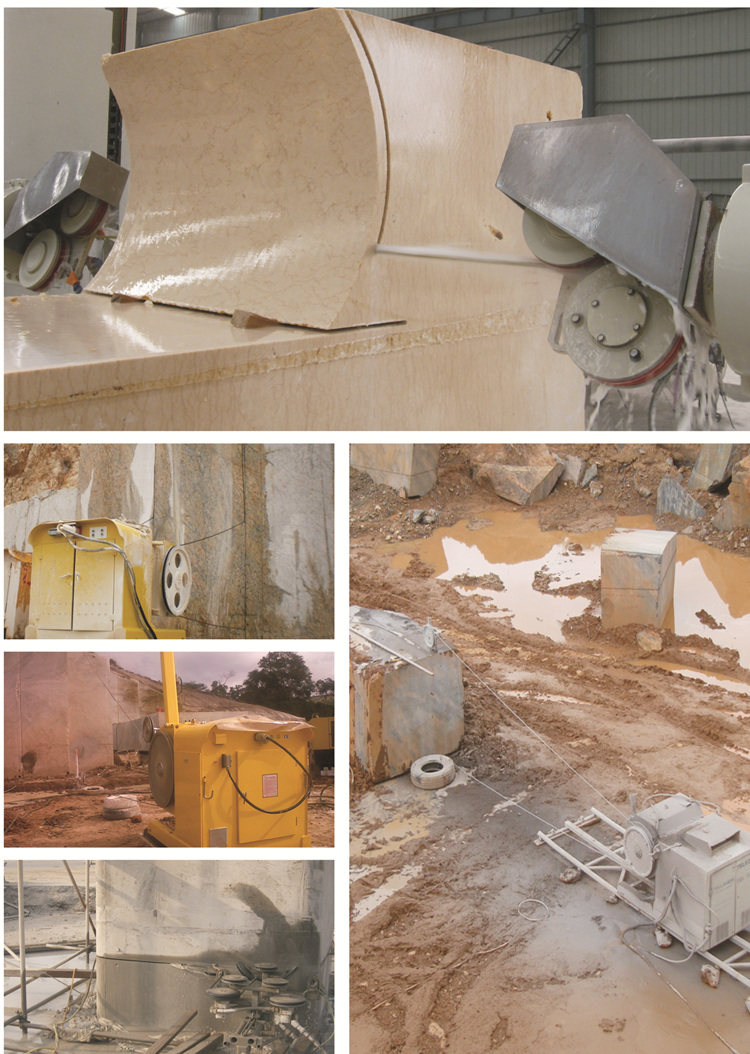

1. Diamond wire saw for granite block squaring

1. Diamond wire saw for granite block squaring

Widely used for granite block squaring

|

Diameter

|

Model

|

Beads/m

|

Coat

|

Cutting materials

|

Line speed(m/s)

|

Efficiency

(m2/h)

|

Life time(m2/m)

|

Beads

|

|

Φ9

Φ10.5

Φ11

|

STX-G-S-P90

STX-G-S-P105

STX-G-S-P110

|

37

|

Plastic

|

Soft

|

24 - 28

|

50 - 100

|

10 – 20

|

Sintered

|

|

Medium

|

20 - 24

|

30 - 60

|

7 – 15

|

|

Hard

|

18 - 22

|

20 - 45

|

5 - 8

|

|

Abrasive

|

22 - 26

|

50 - 100

|

8 - 15

|

2. Diamond wire saw for granite profiling

For processing granite circular slabs, special shapes surface.

|

Diameter

|

Model

|

Beads/m

|

Coat

|

Cutting materials

|

Line speed(m/s)

|

Efficiency

(m2/h)

|

Life time(m2/m)

|

Beads

|

|

Φ8

|

STX-G-P-P80

|

37

|

Plastic

|

Soft

|

22 - 28

|

60 – 80

|

9 – 15

|

Sintered

|

|

Medium

|

20 - 26

|

30 - 60

|

7 – 12

|

|

Φ9

|

STX-G-P-P90

|

Hard

|

18 - 24

|

20 - 35

|

4 - 9

|

|

Abrasive

|

20 - 28

|

60 - 80

|

9 - 12

|

3. Diamond multi-wire saw for granite slab cutting

Widely used in multi-wire saw machine to cut different kinds of grantie slabs.

|

Diameter

|

Model

|

Beads/m

|

Coat

|

Cutting materials

|

Line speed(m/s)

|

Efficiency

(m2/h)

|

Life time(m2/m)

|

Beads

|

|

Φ7.2

Φ8

Φ8.8

|

STX-G-M-P72

STX-G-M-P80

STX-G-M-P88

|

37

|

Plastic

|

Soft

|

25 - 30

|

20 - 30

|

12 – 15

|

Sintered

|

|

Medium

|

20 - 40

|

20 - 25

|

8 – 12

|

|

Hard

|

18 - 22

|

15 - 20

|

5 - 8

|

4. Diamond wire saw for marble block squaring

|

Diameter

|

Model

|

Beads/m

|

Coat

|

Cutting materials

|

Line speed(m/s)

|

Efficiency

(m2/h)

|

Life time(m2/m)

|

Beads

|

|

Φ9

|

STX-M-S-P90

|

33

|

Plastic

|

Soft

|

25 - 35

|

90 – 130

|

28 – 40

|

Sintered

|

|

Medium

|

20 - 32

|

60 - 100

|

23 – 30

|

|

Φ10.5

|

STX-M-S-P105

|

Hard

|

20 - 30

|

50 - 80

|

18 - 25

|

5. Diamond wire saw for marble profiling

|

Diameter

|

Model

|

Beads/m

|

Coat

|

Cutting materials

|

Line speed(m/s)

|

Efficiency

(m2/h)

|

Life time(m2/m)

|

Beads

|

|

Φ8

Φ9

|

STX-M-P-P80

STX-M-P-P90

|

37

33

|

Plastic

|

Soft

|

25 - 34

|

100 – 150

|

20 – 45

|

Sintered

|

|

Medium

|

23 - 32

|

70 - 120

|

22 – 45

|

|

Hard

|

23 - 30

|

50 - 100

|

18 - 30

|

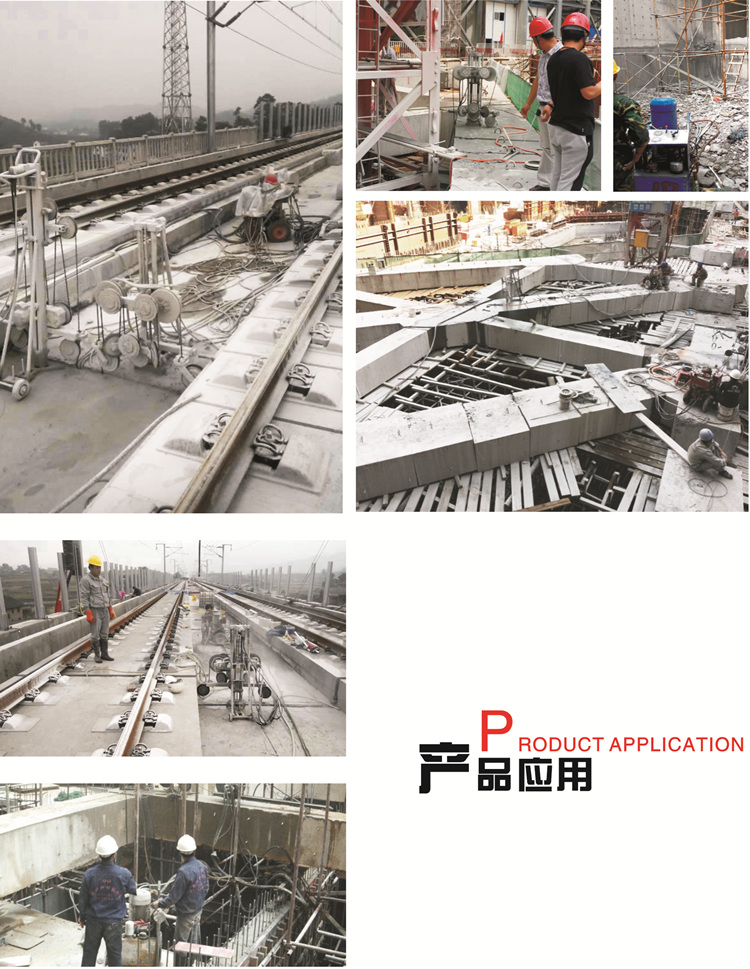

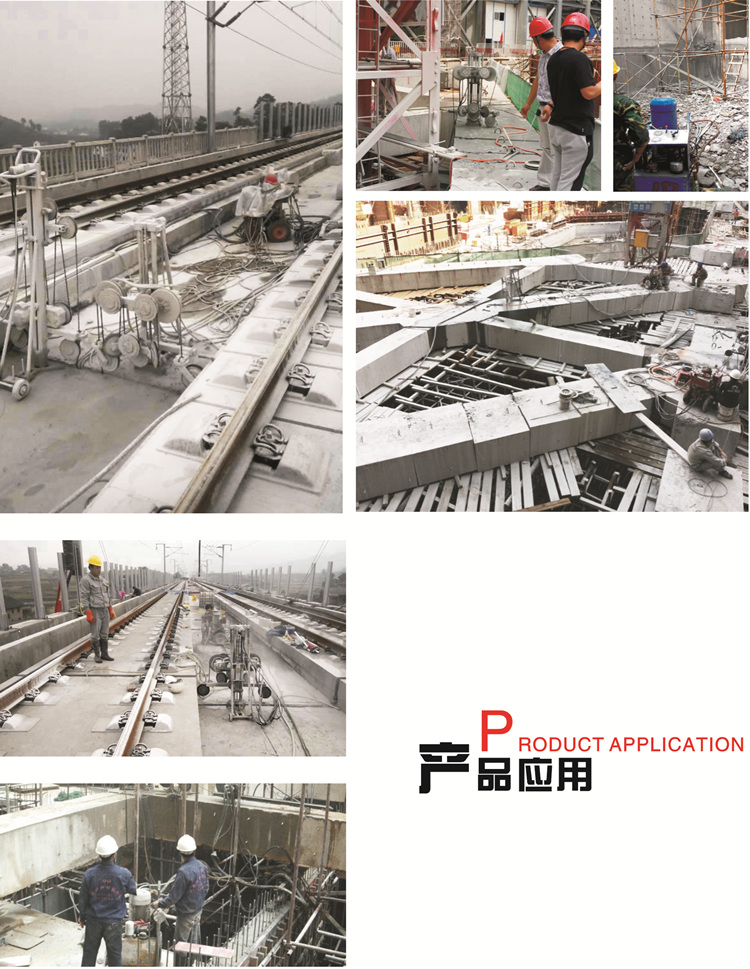

Suggestions for stationary wire cutting machines:

1.The status of beads wear should be regularly inspected, it should be adjusted once unevenly beads wear happens.

2.The status of wear of joints and beads close to joints should be timely checked, and should be replaced timely.

3. Control the cable tension carefully, set it to 250-350KGS for Φ4.9mm steel cable.

4. Change the linear speed of wire according to materials under cutting, following parameters are for reference only:

Hard granite: 20-25m/s

Medium granite: 22-26m/s

Soft granite: 25-29m/s

Hard marble: 28-33m/s

Soft marble: 30-38m/s

5. The linear speed should be 2-3m/s less than normal cutting speed(standard mentioned above) during the sharpening of new wire saw.